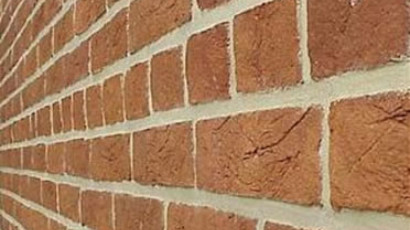

Hybrid Lime Mortar:

This is our defacto mortar specification implemented as standard. Delivering exceptional performance and unrivalled value across the board. It is breathable, flexible, long lasting and hard wearing. It's versatile nature surpasses all other variants of lime mortar design in possesing the widest range of desirable properties in nearly every area. Different ratios and additives are used to gain the desired and sought after properties/attributes depending on its intended application.

Using any number of the predefined ratios of sand, hydrated lime and cement; a wide range of suitable mortar types can be obtained. This category of lime mortar specification is exceptionally tolerant to high content ratios of portland cement binder and offers the best of both worlds by retaining much of the desirable, naturally occuring and widely understood attributes held by lime mortar such as; breathabillity, flexibillity and aesthetic appeal whilst also possessing many of the desirable qualities of a portland cement mortar by way of compressive strength and resistance to abrasion and weathering.

This category of mortar spec remains micro-porous at ratios as strong as 4:1:1, enabling both cavity and solid wall type constructed walls and verticals to benefit, and can also be mixed to ratios as low as 9:2:1, which makes an excellent bridging compound between soft, infirm substrate masonry that may for example, be due to receive a final top coat of strong and somewhat notoriously brittle modern through-colour 'flexible' silicone render. Where a 9:2:1 mortar with an air entrainer/plasterciser, SBR glue and fibreglass-shorts can be added to produce a perfect stepping substrate/bridging mortar between a soft stone wall and stiff final top coat. Any number of ratios can be mixed to suit the nature of the masonry units in a pointing scenario just as well.

• Zoom In •

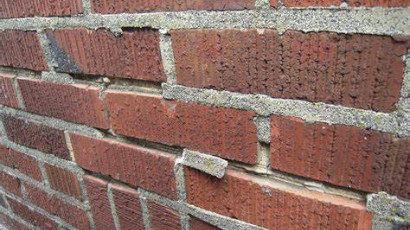

ViewHot Lime Mortar:

Quick lime mortar refers to an ancient form of lime mortar without any additives. It relies solely on carbonation for setting and hardening.

Quick lime mortar is more breathable and flexible than hydraulic lime mortar (NHL), making it suitable for historic restoration projects and buildings of national heritage status.

This type of lime mortar is the original spec mortar design used by the romans and comes recommended to those who must adhere to heritage status regulations on their build project or, for those who require historical consistency and a 'perfect match' to the original bedding mortar of their solid wall, pre-edwardian era structure. This type of mortar is one of the most difficult to work with, the supply chain is very small and akin to cottage industry and the cost per mtr2 is the highest of any of the lime mortar options we offer.

It has a shelf life of around 1 month once kilned and is generally only available by the ton. It is however the pinnacle of repointing mortar in that you simply can't beat repointing a wall with the exact same mortar the masonry units are bedded on.

It posseses all the desired qualities of a lime mortar and is one of the most aesthetically pleasing varieties of mortar design. It falls short only of a hybrid mortar mix in terms of its resistance to weathering, abrasive decay, sparsity in logistical supply and its notoriously fussy handling conditions which nessecitates a pedantic approach and consequential labour intensive overheads, all of which results in significantly higher expense compared to the cost-effective route using a Hybrid Lime Mortar provides.

• Zoom In •

ViewHydraulic Lime Mortar:

Hydraulic lime mortar is a natural hydraulic lime (NHL) or hydraulic lime (HL) that carbonates in a wide range of environments including underwater setting, making it an ideal option for waterways and canals. Contrary to popular beleif, this type of lime is somewhat overstated in its appliance and is not particularly suitable as a 'universal' variant of building lime. It carbonates slowly and will acheive the desired compressive strength after about 2 years however, this material will continue to harden beyond 2 years and is prone to cracking where carbonation exceeds desired margins, rendering the material brittle.

If used as a pointing mortar, it should only be used in areas subject to extreme damp or submersion i.e canals and waterways or, extremely tough stone like granite, where thermal movement in the substrate is minimal. This type of lime mortar is also suitable for areas where high compressive strength is required such as load bearing pad stones for lintels etc.

Lime Putty:

Lime putty is made by slaking quicklime with an excess amount of water.

The resulting product is a smooth paste-like consistency that can be stored and used to create lime mortar by mixing it with sand.

Lime putty mortars have excellent workability and are often used for fine detailing, decorative work, or when working with soft or fragile masonry.

Proper maturation of lime putty for a prolonged period is crucial to workability and long-term performance, all our lime putty is sourced from reputable suppliers who provide a suitable readily usable product, cured for at least six months in a certifiably appropriate environment that allows evaporation and drainage, delivered ready for use in a pointing mortar, internal plaster or external lime render mix.

Non-Hydraulic/Hydrated Lime:

Non-hydraulic lime mortar is produced by heating the lime before slaking it with water. This process helps to accelerate the slaking reaction and produce a more homogeneous mixture.

Non-Hydraulic lime mortar is often referred to as Hydrated Lime or Lime Hydrate. It has very little compressive strength and is generally used as a conditioner when implemented as a building material. IT is sometimes used to 'soften' NHL based mortar mixes but more often is used alongside a portland cement binder as an improver / additive.

Non-Hydraulic lime should not be used on its own as a binder in a mortar mix. It should only be used as an additive or conditioner alongside quicklime/hot, NHL, or portland cement.

• Benefits of Breathable Lime Pointing Mortar

Flexibility & Breathability:

Lime mortar is more flexible and breathable than cement-based mortar. It allows moisture to evaporate from the masonry, reducing the risk of trapped moisture and subsequent damage. This breathability is particularly important for older or historic buildings constructed with softer materials that need to "breathe" and release moisture.

Compatibility:

Lime mortar is compatible with a wide range of masonry materials, including historic brick, stone, and earth construction. It accommodates the natural movement and expansion of these materials over time, reducing the risk of cracking and damage.

Self-Healing & Repairability:

Lime mortar has a unique ability to self-heal. It can re-crystallize and repair small cracks that may occur in the masonry over time, helping to maintain the integrity of the structure. Additionally, if repairs are required, lime mortar can be easily removed and replaced without damaging the surrounding masonry.

Aesthetics:

Lime mortar provides a softer, more aesthetically pleasing finish compared to cement mortar. Its natural color and texture complement historic buildings and contribute to their visual appeal. Lime mortar also allows for better integration with existing masonry and helps to preserve the authenticity and character of older structures.

Environmental Considerations:

Lime mortar is an environmentally friendly choice. It has a lower carbon footprint than cement due to its lower energy requirements during production. Lime is also a natural and abundant material that can be sourced fairly local however some types of lime are particularly tricky to obtain due to its obscurity and cottage industry like supply chain.

• CONSIDERATIONS

These are just a few examples of lime mortars. The specific type of lime mortar used in a construction project depends on factors such as the type of masonry, climate, exposure to moisture, and desired performance characteristics. Always follow local building codes and guidelines when selecting the appropriate lime mortar for a particular application.

It's worth noting that lime mortar is not a catchall solution for every type of use and may not be suitable for certain applications. Modern construction practices and specific building requirements may call for alternative materials. It's important to consult with professionals experienced in historic preservation or conservation to determine the most appropriate mortar choice for a given project.

Call Tameside Pointing today for a free consultation, where further information can be given in respect of the nuances of your projects needs.